English - Global

English - Global

Russian - Kazakhstan

Arabic - KSA

Gas Dispersion Analysis using Computational Fluid Dynamics (CFD)

We have considerable experience in performing Gas Dispersion Analysis using Computational Fluid Dynamics (CFD) studies for the following applications:

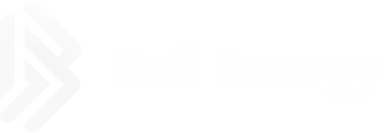

- Predicting realistic flammable and toxic gas cloud sizes using CFD dispersion capabilities

- Predicting toxic gas cloud sizes and its impacts on occupied areas, escape routes

- Recommending design improvements to reduce potential for gas accumulation

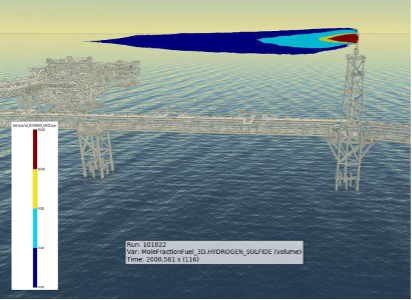

- Optimizing the offshore bridge lengths and separation distances between accommodation and processing facilities based on effects of flammable and toxic gas dispersion, accumulation and ignition

- Determining flare location and height

Such CFD studies are very crucial for Offshore Oil & Gas platforms, FPSO, FSO and in onshore facilities that process of handle toxic chemicals such Hydrogen Sulphide, Hydrogen Cyanide, Sulphur Dioxide.

Applications of CFD in Gas Dispersion Analysis

The type of applications where CFD is used as a tool for Gas Dispersion Analysis include the following:

- CFD Flammable Gas Dispersion Analysis: In this study, we perform ventilation assessment, identify congested regions and determine the various flammable gas cloud shapes and sizes that have the potential for accumulation. This is usually followed by or part of a more comprehensive CFD Probabilistic Explosion study.

- CFD Toxic Gas Dispersion Analysis: CFD can be used to determine realistic toxic gas clouds and its impact on adjacent platforms, escape routes, buildings, occupied areas etc. This study can also be used for onshore facilities, especially where high toxicity is involved or where facilities are surrounded by populated areas.

- CFD Flare Dispersion Analysis: CFD can be used to determine realistic toxic and flammable gas dispersions from the flare due to flame-out conditions or determine the dispersion of combustion gases such as CO2 and SO2.

- CFD Hot Plume Assessment: CFD can be used to determine the temperature of air in the vicinity of stacks. This is crucial especially where stacks are located close to helicopter landing areas where the hot plume can impact helicopter landing & take-off.

What are the benefits of CFD based Dispersion study?

- Improve ventilation of regions by re-orienting equipment to reduce explosion overpressure potential

- Determine flammable gas dispersion and accumulation potential and its impact on hazardous area classification, equipment layout

- Determine optimum separation distances between process areas and buildings based on flammable, toxic dispersion outcomes

- Strategize escape and evacuation requirements

- Determine location and height of flare based on dispersion outcomes due to flame-out conditions or combustion gases such as SO2 and CO2.

- Determine dispersion of hot plumes and the impact from stacks onto helidecks

- Optimize Fire & Gas Detector locations based on reasonable gas cloud sizes determined from CFD dispersion analysis

- Obtain realistic results using CFD as compared to other empirical or phenomenal tools

How can Bell Energy help?

Our CFD Engineers utilize a formal and systematic approach in performing CFD based dispersion and explosion studies. Bell Energy has developed in own cluster computing facility for running multiple CFD scenarios concurrently and coupled with in-house post processing productivity tools, Bell Energy is capable of completing CFD studies within shorter time without impacting quality of the outcomes. For projects where several thousands of scenarios need to be run concurrently, Bell Energy utilizes Third Party cluster computing facilities world-wide.

Next

Industries