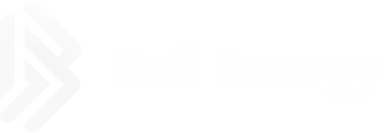

FEED and Detailed Engineering

Comprehensive engineering services

Bell Energy offers comprehensive engineering services from pre-FEED and front-end engineering (FEED) to detailed engineering for project delivery at every phase. Our team of engineers delivers sustainable, safe and cost-effective solutions for clients based on our unique digital-focused approach and years of experience in engineering and design. Our engineers’ vision is to design and build any asset considering its full lifetime and meeting the client’s specific requirements with compliance to National and International standards.

Our Engineering Team and Expertise

Our Engineering Team is composed of highly-qualified Engineering Managers, Process Engineers, Electrical Engineers, Risk & Safety Engineers, Design HSE Engineers, Instrumentation Engineers, Corrosion & Materials Engineers, CAD Modelers and other engineering professionals who have extensive experience in delivering complete engineering design.

Our Engineering offerings to multiple sectors

- Onshore and Offshore Oil & Gas

- Mining & Metals

- Fertilizers & Petrochemicals

- Infrastructure & Roads

- Housing & Residential Complexes

- District Heating and Cooling

Related Insights

Front-End Engineering Design

Our engineers provide the full scope of pre-FEED and FEED services, and all types of engineering studies with the aim to analyze the project’s technical requirements, fix the design basis and process design, as well as provide a preliminary investment cost for the project execution allowing contractors and suppliers to issue a firm quotation.

Our engineers provide the full scope of pre-FEED and FEED services, and all types of engineering studies with the aim to analyze the project’s technical requirements, fix the design basis and process design, as well as provide a preliminary investment cost for the project execution allowing contractors and suppliers to issue a firm quotation.- Development of Process Development Package

- Development of Project Philosophies

- Site Selection Study

- Geotechnical & Topographical Surveys

- Process Engineering Package

- Development of Plot Plans

- Process Simulation (Steady State & Dynamic)

- Process Flow Diagrams

- Piping & Instrumentation Diagrams

- Pipeline Route Section

- Preliminary Bill of Materials and Bill of Quantities

- Mechanical Design

- Structural Design

- Civil & Architecture

- Plot Plans and Hazardous Areas

- Piping Layouts & General Arrangement

- Instrument, Electrical and Civil Works Layouts

- Automation

- Preliminary 2D & 3D Models

- Major Equipment List

- HAZOP And Safety Studies

- Engineering Design Package Development

- FEED Dossier (with Project Timeline, CAPEX & OPEX Estimates)

Detailed Engineering

On the basis of the developed FEED package and basic engineering package, our teams can further provide Detailed Engineering services allowing our clients to obtain precise and detailed deliverables, including final drawings and specifications for execution of the project.

On the basis of the developed FEED package and basic engineering package, our teams can further provide Detailed Engineering services allowing our clients to obtain precise and detailed deliverables, including final drawings and specifications for execution of the project.- Piping and Instrument Diagrams

- Detailed Piping Drawings, including Stress Calculations and Isometrics

- Detailed Drawings for Civil Works, Electrical Facilities and Instrumentation

- Final 3D Models

- Detailed Bill of Materials and Bill of Quantities

- Management of Vendor Drawings, Vendor Datasheets

- Material Selection Diagrams

- Cost and Schedule Control

- Start-up Procedures

Our solutions for all disciplines in any industry

Process

- Process Design & Calculations

- Plant Engineering and Design

- Process Optimization

- Process Intensification

- Process Control

- Physical Design

- Process and System design

- Process modeling and simulation

- Process safety and relief system design

- Integration

- Development of PFDs, P&IDs

- Utility Flow Diagrams (UFDs)

- Heat & Material Balances (HMB)

- Development of Process Datasheets

- Line Lists

- Tie-in Schedules

- Batch And Continuous Process Development

- Energy “PINCH” Analysis

- Material & Energy Balance Preparation & Simulation

- Process Equipment Sizing, Specification, And Selection

- Process Instrument And Valve Sizing, Specification, And Selection

- Process Debottlenecking and Expansion

- Pilot Plant Design, Operation And Scale Up

- Process Control Narrative Development

- Process HAZOP

- SIL (Safety Integrity Level) Report

- Safety Design Philosophy

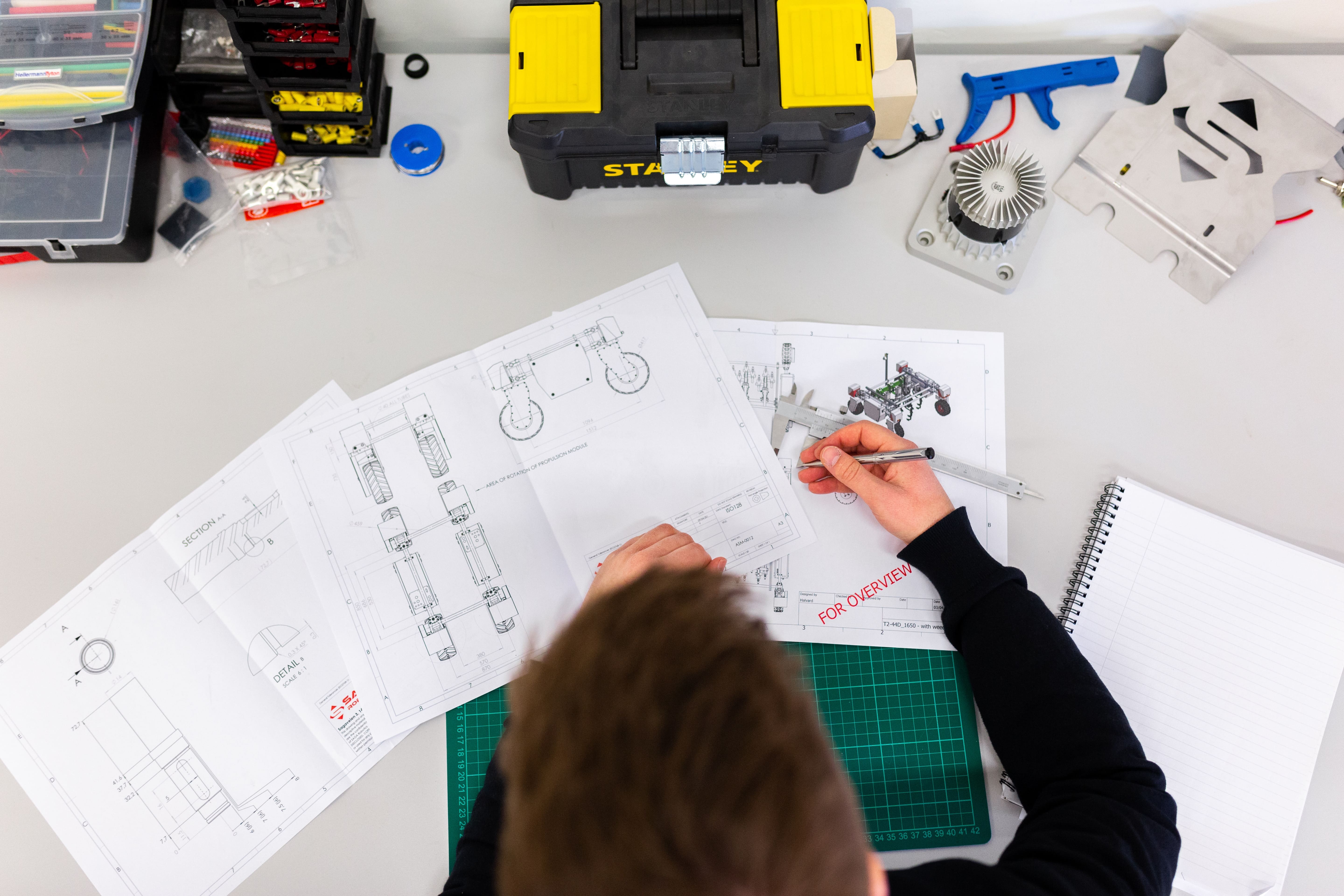

Electrical

- Complete Electrical & Power Project Engineering

- Estimating and Scheduling For New Installations

- Modifications of Existing Systems

- Field Survey of Existing Systems With Recommendations of Improvement

- Providing Field Engineers and Technicians for Monitoring New Installations And for Checkout and Start-up

- Single Line Electrical Diagrams

- Load Flow Diagrams

- Main Substation Planning

- Electrical Power Distribution Systems

- Electrical Load Lists

- Emergency Power Load Requirements

- Hazardous Area Classification Drawings

- Emergency Power One Line Diagrams

- UPS One Line Diagrams

- Electrical Bulk Material Lists

- Electrical Equipment Drawings and Specifications

- Electrical Equipment Sizing Calculations

- Motor Datasheets

- Grounding, Substation, Switchgear Building Equipment Layouts

- Electrical Installation Details

- Plant Cable Tray and Cable Routing Layouts

- Electrical Lighting Control Schematics

- Electric equipment list (Transformers, Switchgears, MCCs, UPS, Chargers, Generators, Power Supplies, Transformer (Potential Transformer (PT) and Current Transformer (CT)), Control Panels, Packaged equipment etc.)

- Motor Control Center Layouts

- Power Systems Analysis

- Branch Circuit Layouts & Panel Scheduling

- Electrical System Studies

- Fault Current, and Coordination Studies

- Arc Flash Studies And Mitigation

- Motor Elementaries and Indoor / Outdoor Lighting

- Electrical Floor Plan Layouts

- Fire Protection & Security Systems

- Electrical Check-out & Start-up

- System Trouble Shooting and Existing System Documentation

- Electrical Gear and Installation Services

Instrumentation and Control

- Complete instrument project engineering

- Estimating and Scheduling For New Installations

- Modifications Of Existing Systems

- Logic & ladder diagrams

- Control room layouts

- Programmable controller field wiring diagrams

- Upgrading existing control systems from conventional electronic or pneumatic control to distribute/plc control, with minimum loss of production

- Instrument Datasheets and Calculations

- Control Logic Diagrams

- Input/ Output Schedules

- Cause and Effect (C&E) Diagrams

- Instrument and Control System Schematics

- Instrumentation loop diagrams

- System Block Diagrams

- Instrument Cable Routing and Schedules

- Instrument Hook-Up Diagrams

- Power Distribution Schedules

- Motor elementaries

- Computer room design

- Existing system documentation

- Control panel layouts

- PLC & DCS configuration

- Instrumentation check-out & start-up

- Diagnose, troubleshoot and verify the fail-safe design of new and existing safety systems such as flame safety on lime kilns and boilers

- Fire & Gas Systems Engineering:

- Detector 3D Mapping

- Fire & Gas Detector Engineering

- F&G Testing & Maintenance Services

Piping

- Pipe Specifications and Drawings

- 3D Piping Modeling, Design, Orthographic Plan, Section, and Detail Preparation

- Fabrication Isometric Development

- Bill of Material

- Above and Below Ground Piping Systems

- Thermal and Dynamic Pipe Stress Analysis And Design

- Standard and Custom Pipe Support Design

- Piping System Walkdowns

- Piping Installation Quality Audits

- Process Piping Design

- Utility Piping Design

- Heat Tracing/Jacketing Specification and Schedules

- Piping Material Take-offs (MTOs)

- Wide Range Of Piping Specifications including Carbon Steel, Galvanized,, Copper, PVC and CPVC, Teflon and Polypropylene Lined Pipe, Glass Lined Pipe, Ductile Iron, HDPE, Polypropylene, Fiberglass Stainless Steel, Duplex and Super Duplex Stainless

- Flammable and Volatile Liquid & Gas Piping Systems

- Bio-Gas Piping

- Plumbing Systems

- Pipe Supports Design

- Pipe Support Spring Register and Calculations

- Fabrication and Installation of Pipe-work Specification

- Isometric (ISO) drawings

- Stress Analysis Specifications

Mechanical

- Mechanical Design of Equipment

- Mechanical Datasheets, Equipment Lists

- Mechanical Schematic Diagrams

- Equipment Arrangement Drawings

- Material Handling System Design: Pneumatic Conveying (Dense, Dilute, Positive, and Negative), Mechanical Conveying, Weighing, Feeding, and Blending, Bulk Receiving and Loadout (Truck and Rail), Storage, Reclaim, Silos, Bins, etc., Chutes, Spouts, and Ductwork

- Utility System Design: Boilers, Steam and Condensate Systems, Compressed Air Systems, Cooling Tower and Chilled Water Systems, Vacuum Systems

- Production, Manufacturing, and Process Facility Layout

- Process Aspiration & Dust Collection System Design

- Dry and Liquid Storage and Handling Facility Design

- Industrial Building Ventilation and HVAC Design

- Mechanical Design And Analysis: Specialty Machine and Mechanism Analysis, Design and Improvement, Finite Element Analysis, Thermal Stress Analysis, Hydraulic Power Units, Circuit and Component Specification, Analysis, and Design

Civil and Structural

- Civil & Structural Engineering and Design

- Design of Infrastructure, Utilities & Offsites

- Site Selection Studies

- Civil, Piping, Buildings, Cable Trench, Structural Steel, Road Layouts

- Earthworks Specifications and Grading Drawings

- Foundation & Concrete Drawings and Specifications

- Structural Steel Drawings

- Underground Services and Specifications

- Equipment Support Structures Towers

- Industrial Structures

- Moment Frames

- Braced Frames

- Pipe Bridges

- Personnel Bridges

- Material Handling Conveyor Galleries

- Monorail / Hoist Systems

- Rail Unload Pits Per Arema Guidelines

- Truck And Rail Loadout

- Deep Foundations

- Mat / Spread Footings

- Slabs On Grade

- Cast In Place Concrete Structures

- Pre-cast Concrete Structures

- Post-tensioned Concrete Structures

- Masonry Structures

- Elevated Concrete Slabs

- Truck and Rail Unload Pits

- Industrial Building Cladding Systems

- Access And Egress Structures

- Fire Protective Coatings / Systems